- 17

- Feb

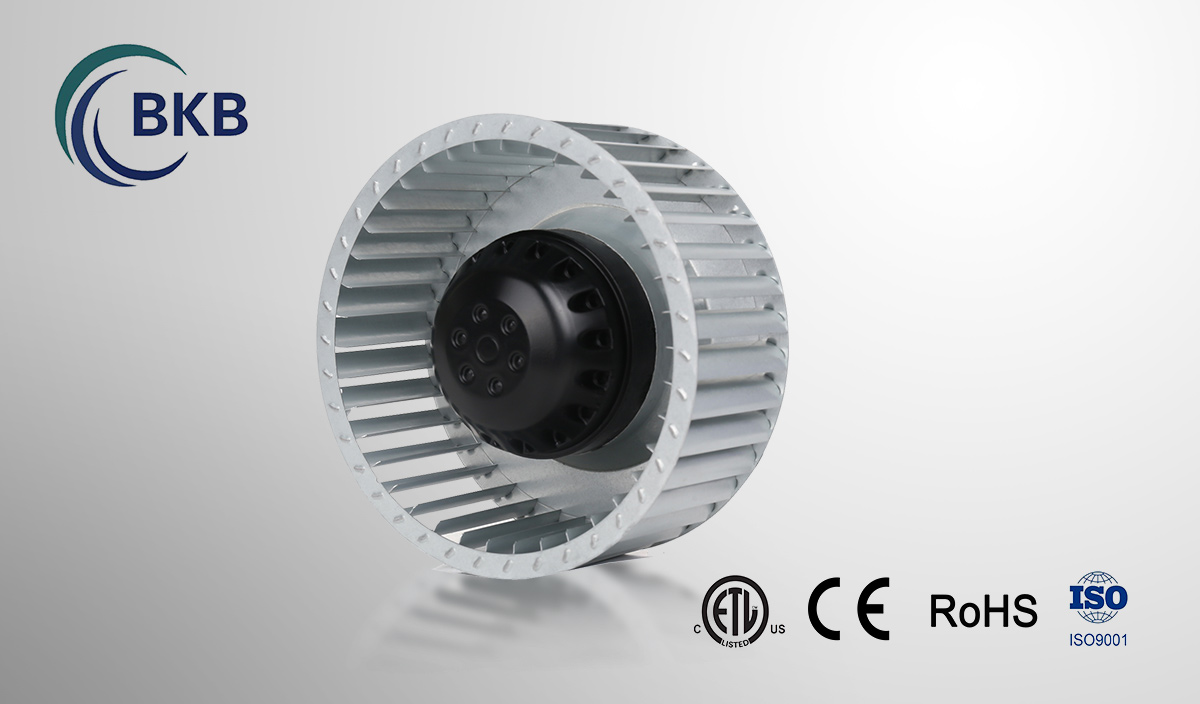

What fan is suitable for drying equipment ( Dryer/ Drying oven/Drying cabin)

The dryer needs centrifugal fan in the normal drying process,

Then there are some matters needing attention when using centrifugal fan for dryer equipment,

It can help you improve the efficiency and output and ensure the safe production of drying equipment.

The selection method of centrifugal fan in dryer industry involves the following situations in actual operation and production:

1) Select the appropriate centrifugal fan model for the new drying project:

The mass flow and total pressure of the centrifugal fan are determined mainly according to the production capacity and resistance of the drying equipment system.

For a single induced draft fan system, ensure that the total pressure of the centrifugal fan is greater than the system resistance.

In the case of double induced draft fan system, the sum of the total pressure of the two centrifugal fans shall be greater than the resistance of the system.

The centrifugal fan is selected. Generally, the model is determined according to the curve of the centrifugal fan.

The centrifugal fan can well meet the operating conditions required by the drying equipment system, so as to maximize the production efficiency of the fan;

2) For the existing drying equipment system, due to the requirements of increasing production and other factors, it is necessary to determine the transformation scheme of centrifugal fan:

Generally, it is required to determine the variation range of air volume according to the actual needs of production, and then determine the transformation scheme of centrifugal fan;

3) When the operating conditions of centrifugal fan change, check the capacity of centrifugal fan:

When the air temperature at the centrifugal fan of the dryer changes, especially when the actual temperature is much lower than the design temperature, the motor may be overloaded and burned in serious cases.

How should the centrifugal fan in the dryer be arranged?

In the drying equipment system, the commonly used fan is centrifugal fan.

The placement method of centrifugal fan in the drying system can be either single induced draft fan or double induced draft fans.

These two methods have their own characteristics:

A single induced draft fan is placed after the dust recovery equipment to make the drying equipment operate under negative pressure.

The advantage of this dry system is that dust and harmful gases will not leak into the atmospheric environment, but because of the high negative pressure in the drying equipment,

Frequent start and stop of centrifugal fan will cause partial instability in the tower and external air leakage into the dryer,

Therefore, the single induced draft method is only suitable for small drying systems.

For large-scale drying equipment, two centrifugal fans are mainly selected, one as blower and the other as induced draft fan.

This system has great flexibility and can improve the operating conditions of the dryer through regulating the pressure distribution of the pipeline, so that it can operate under the micro negative pressure close to the atmospheric pressure.

This not only coordinates the advantages of negative pressure operation, but also avoids the defect of dry power reduction due to air leakage into the system due to large negative pressure operation,

A micro negative pressure operation can ensure that the dust recovery equipment has the highest recovery rate.