- 14

- Apr

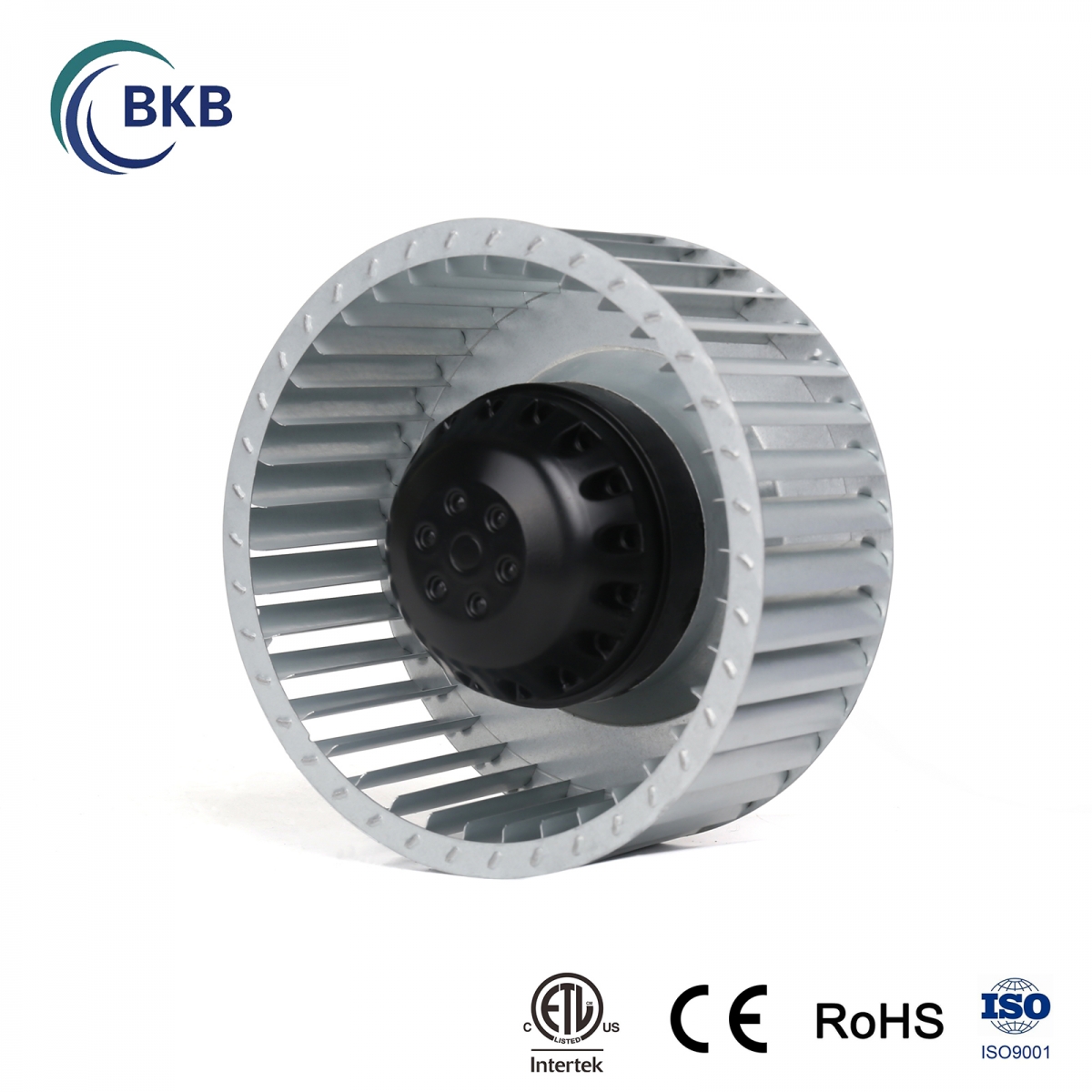

The main parts of a centrifugal fan.

The main parts of a centrifugal fan are:

- Fan housing

- Impellers

- Inlet and outlet ducts

- Drive shaft

- Drive mechanism

- Fan Dampers and Vanes

- Inlet and outlet ducts

- Fan blades

- Fan discharge casing

Other components used may include bearings, couplings, impeller locking device, fan discharge casing, shaft seal plates etc.

Drive mechanism

The fan drive determines the speed of the fan impeller (impeller) and the variation range of this speed. There are two basic types of fan drives.

Direct

The fan wheel can be directly connected to the shaft of the motor. This means that the fan wheel speed is the same as the motor speed. Direct drive is the most effective form of fan drive because there is no loss in switching from motor speed to fan speed.

Some electronics manufacturers Manufacture centrifugal fans with external rotor motors (the stator is inside the rotor), and the rotor is directly mounted on the fan impeller (impeller).

Belt

A set of pulleys is installed on the motor shaft and fan shaft, and the belt transmits the mechanical energy of the motor to the fan.

The fan wheel speed depends on the ratio of the motor pulley diameter to the fan pulley diameter. The fan speed in the belt driven fan is fixed unless the belt slips. Belt slip will reduce the fan speed by hundreds of revolutions per minute (RPM). [19] The belt also introduces additional maintenance items

Azimuth

Bearing is an important part of fan. Sleeve bearings are used in residential and small fan applications, such as ball bearings. Special bearings, such as water-cooled sleeve bearings, can be used in industrial applications to exhaust hot gas. [20]

Many turbine blowers use air bearings or magnetic bearings. [21]

Speed control

The fan speed of modern fan is realized through the variable frequency driver that directly controls the motor speed. The motor speed can be raised and lowered according to different air flow. The amount of air moved is nonlinear to the motor speed and must be individually balanced for each fan. Typically, this is done by the test and balance contractor at the time of installation, although some modern systems use instruments to directly monitor the air flow near the outlet and can use feedback to change the motor speed.

Older fan installations will use inlet or outlet blades – metal baffles that can be opened and closed at the fan outlet. When the blades are closed, they increase the pressure and reduce the airflow of the fan. This is less efficient than VFD because VFD directly reduces the power consumption of the fan motor and the blades work at a constant motor speed.